At Masters & Young, we recognize that Printed Circuit Board (PCB) assembly is a crucial phase in electronics manufacturing. As a leading electronic design and manufacturing company, we aim to help our clients make informed decisions by explaining the primary factors that influence PCB assembly costs.

Component Selection

The choice of components plays a significant role in determining the overall cost of PCB assembly. While the PCB substrate itself (whether FR-4, polyimide, or metal-core) contributes to the expense, it’s typically minor compared to the cost of components such as integrated circuits (ICs), resistors, capacitors, and connectors.

Design Complexity

The intricacy of your PCB design directly impacts the assembly cost. Multi-layer boards with high component density are naturally more expensive to produce than simpler, single-layer designs. At Masters & Young, we have the expertise to handle a wide range of design complexities, ensuring efficient assembly while maintaining competitive pricing.

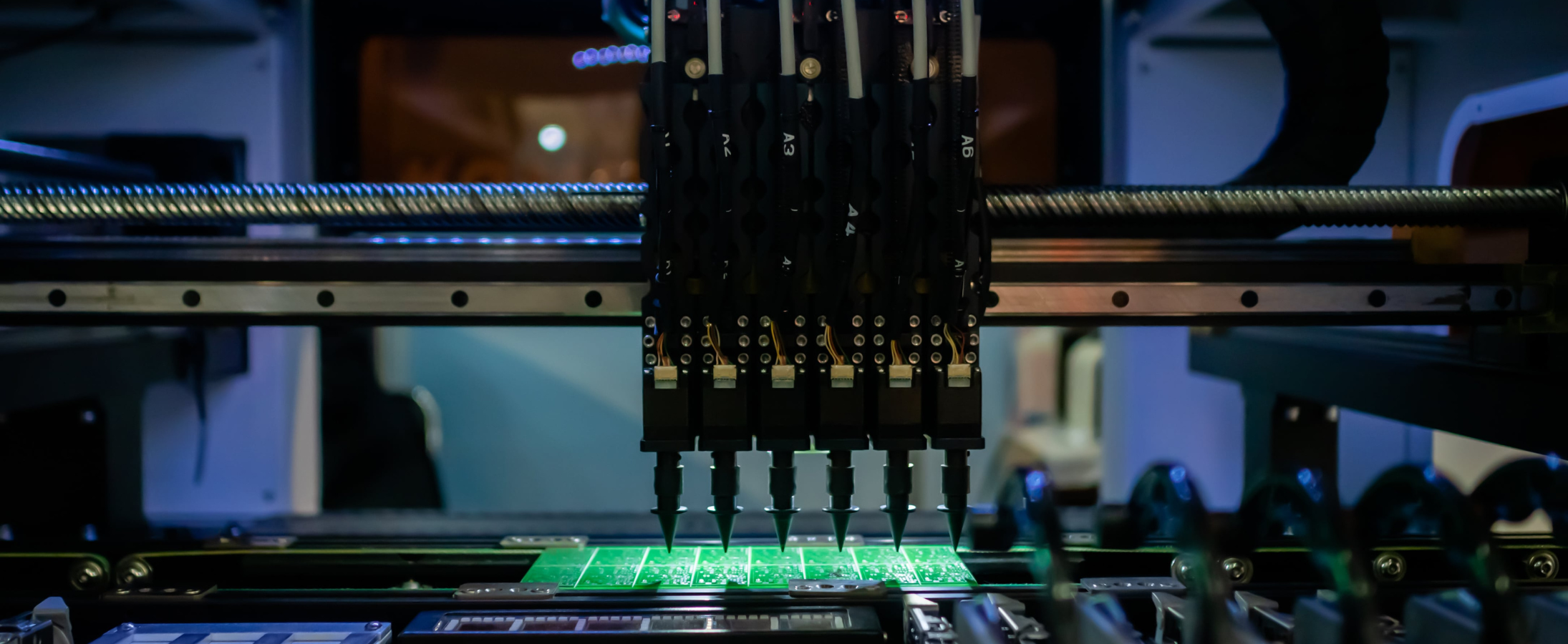

Assembly Techniques

The choice between surface-mount technology (SMT) and through-hole assembly significantly affects the overall cost. SMT is generally more cost-effective for large-scale production, while through-hole assembly may be pricier due to its labor-intensive nature. Our team at Masters & Young is proficient in both techniques, allowing us to recommend the most suitable and cost-effective option for your project.

Quality Assurance

Rigorous testing and quality control are essential for high-quality PCB assembly. The extent of testing required, such as functional testing, in-circuit testing, and automated optical inspection, can impact the final cost. At Masters & Young, we prioritise thorough testing and compliance procedures to ensure you receive a reliable product, minimising the risk of costly defects in the long run.

Production Volume

The quantity of PCBs needed can significantly influence the per-unit cost. Larger production runs often benefit from economies of scale, potentially reducing the cost per board. At Masters & Young, we cater to both small batch productions and large-scale manufacturing, providing cost-effective solutions tailored to your specific needs.

Turnaround Time

The urgency of your project can affect the overall cost. Expedited services may incur additional charges due to the need for dedicated resources and potential overtime. We at Masters & Young strive to balance quick turnaround times with cost-effectiveness to meet your project deadlines without compromising quality.

By understanding these factors, you can make more informed decisions about your PCB assembly projects. At Masters & Young, we’re committed to providing high-quality, cost-effective PCB assembly services. Our advanced tools and expertise allow us to handle intricate designs while maintaining efficiency and quality.

For your next PCB assembly project, trust the experts at Masters & Young. Contact us today to discuss how we can streamline your electronic design and manufacturing needs.