Together, we work with innovation seeking companies to find ingenious solutions to complex problems, and we deliver with excellence to empower our customers to realise exciting commercial opportunities.

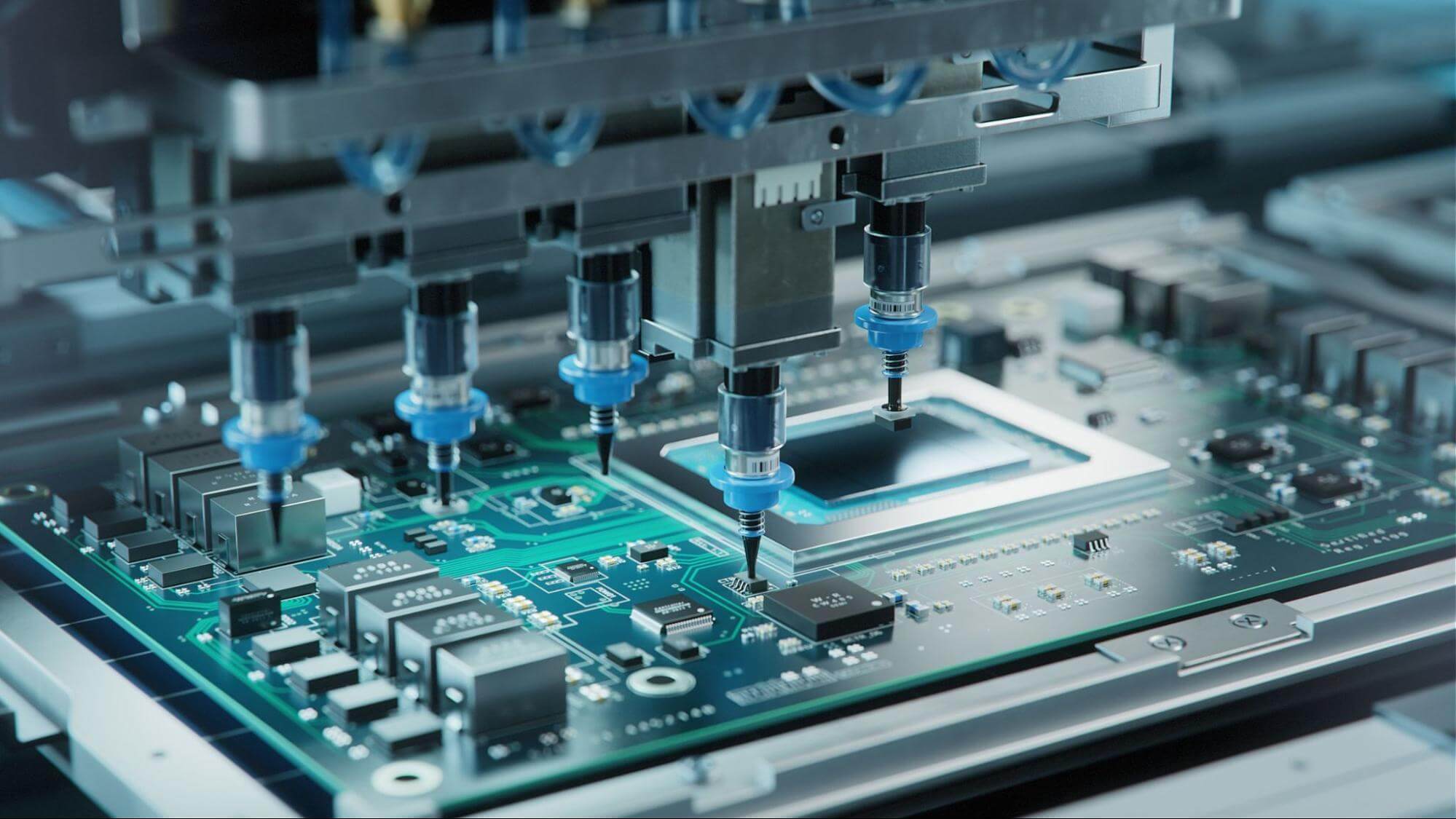

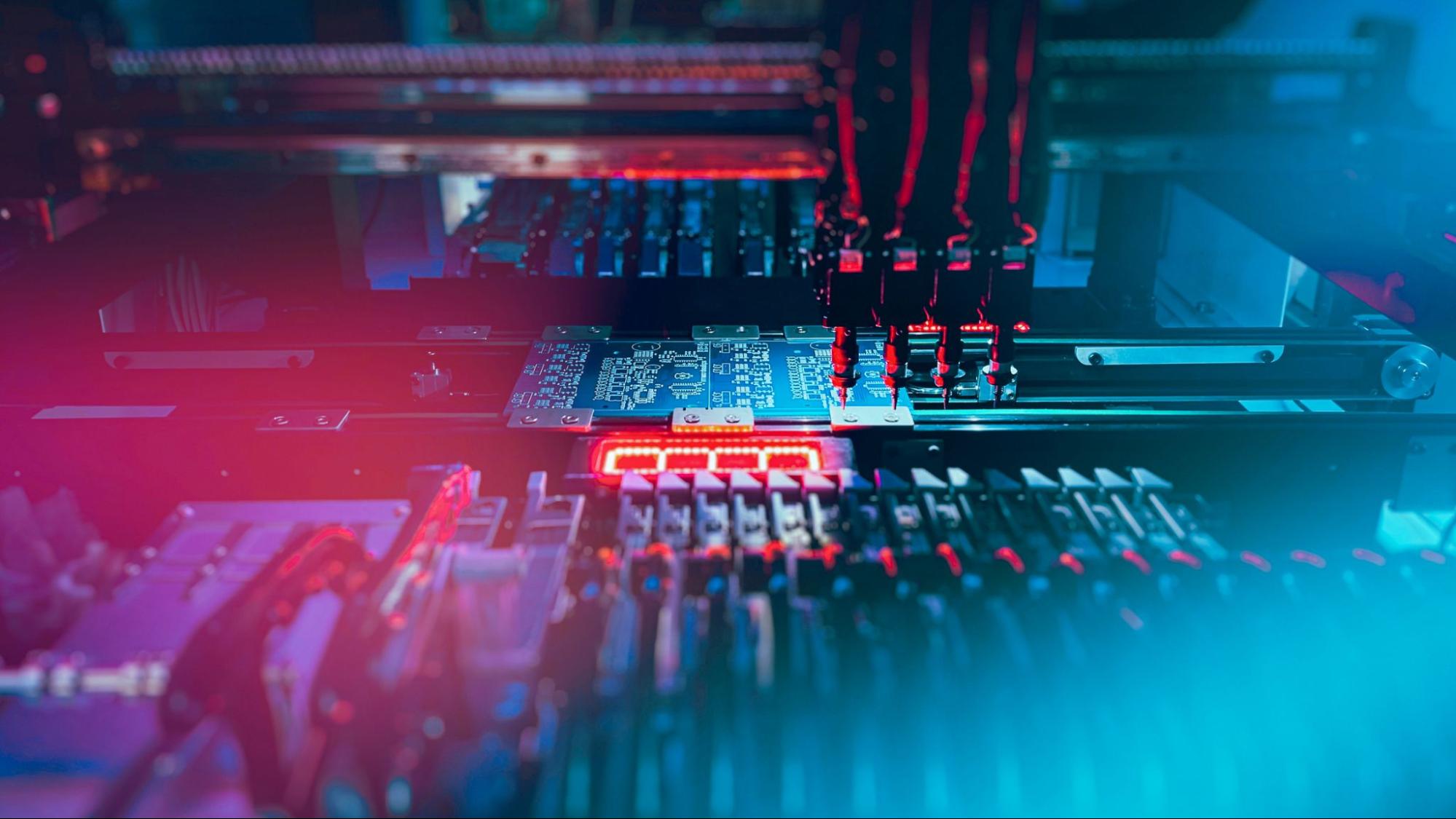

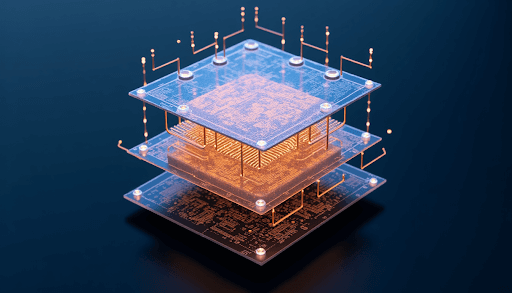

Leading the Way in Electronics R&D and Manufacturing Excellence

Together, we work with innovation seeking companies to find ingenious solutions to complex problems, and we deliver with excellence to empower our customers to realise exciting commercial opportunities.

Leading the Way in Electronics R&D and Manufacturing Excellence

Trusted by market leaders, our Define, Design and Deliver methodology provides the highest quality Electronics, PCB’s and best-in-class solutions.

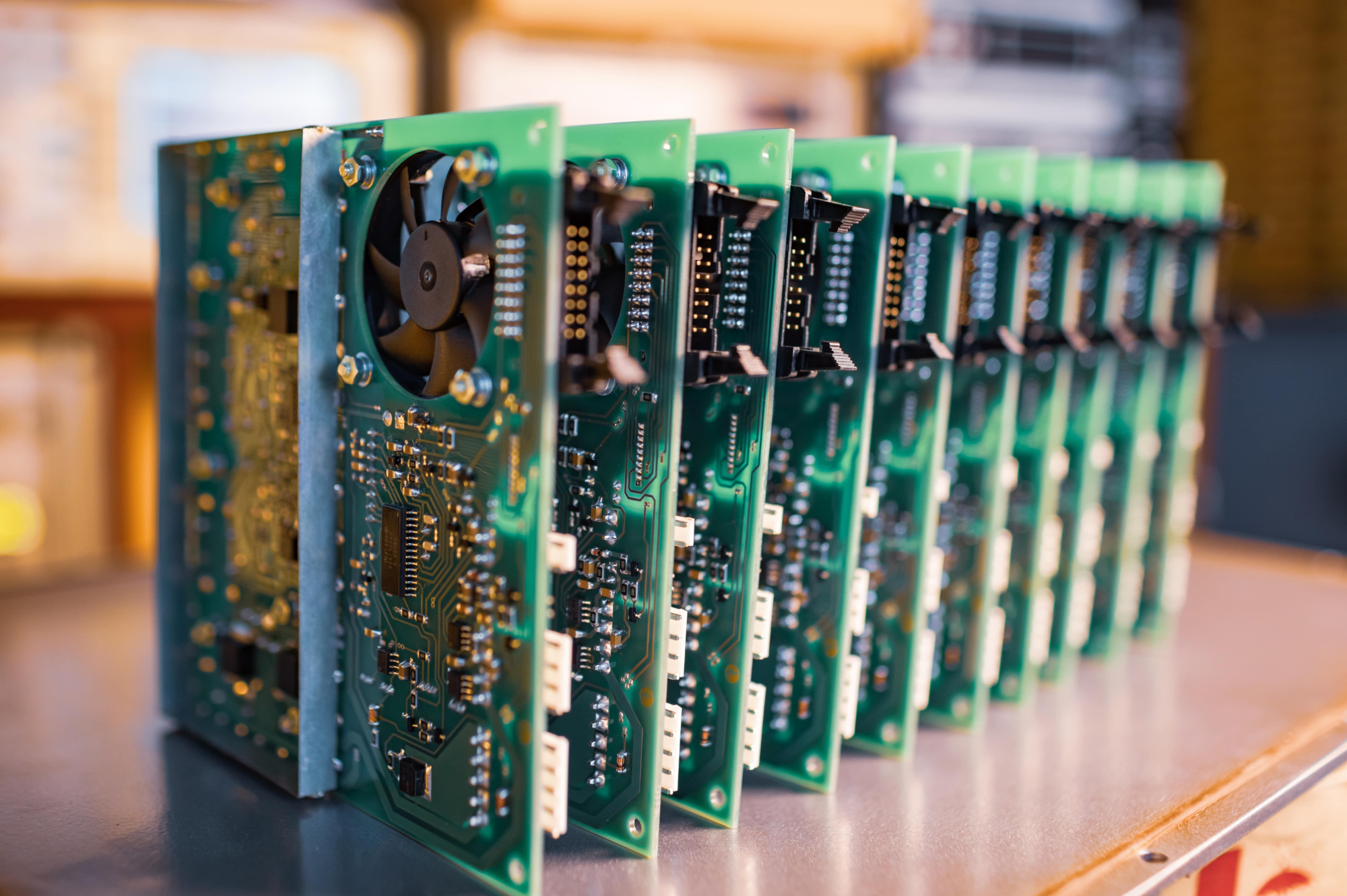

Established in 1997, Masters & Young is a market-leading, high-end electronic design and manufacturing company. Our experienced team is focused on providing quality solutions for a wide range of industries, including Defence, Aerospace Mining and Medical.

With decades of expertise, we specialise in delivering cutting-edge technology and precision-engineered solutions tailored to meet the unique demands of each sector we serve. Our commitment to innovation and excellence ensures that every product meets stringent industry standards, offering reliability and performance in even the most demanding environments.

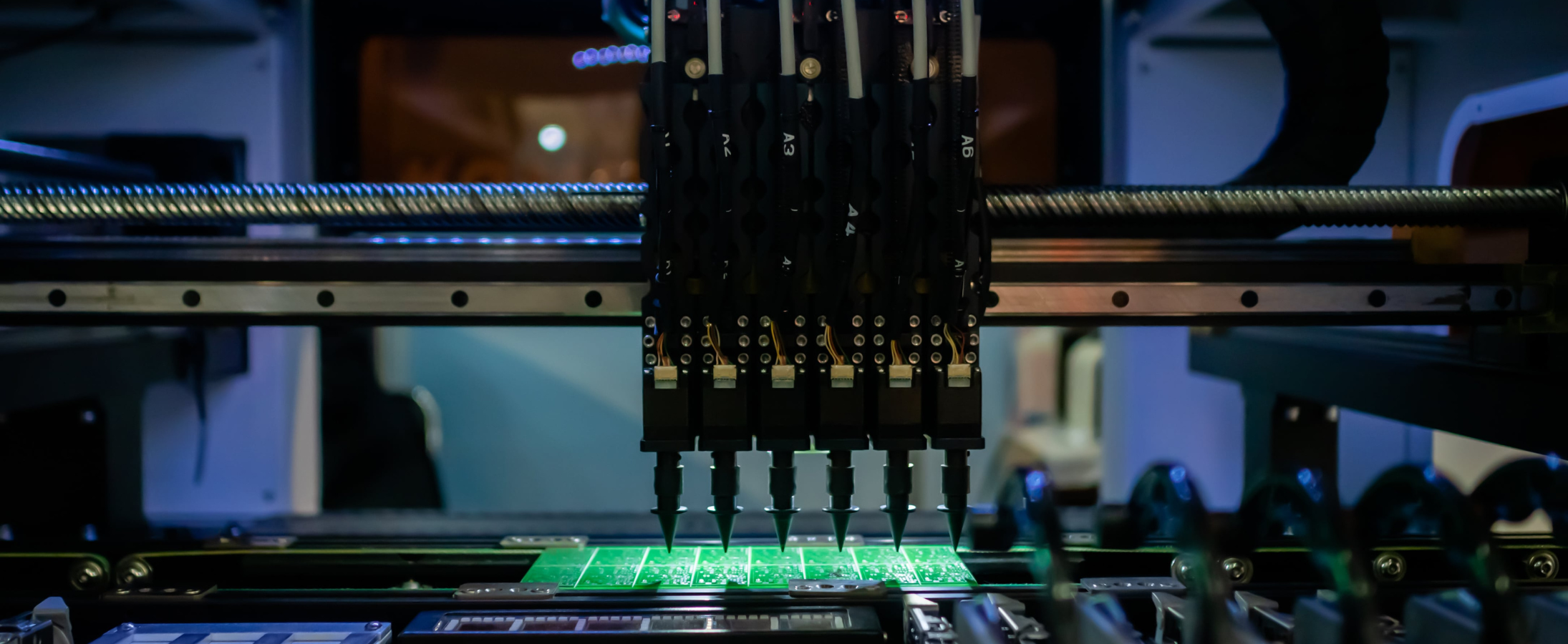

By leveraging the latest advancements in electronics and PCB manufacturing, we provide our clients with scalable, high-quality solutions that drive efficiency, safety, and success in their operations.

At Masters & Young, we manufacture with precision and dedication, turning complex challenges into groundbreaking technological achievements.

We specialise in designing and producing high-quality PCBs for Defence, Medical, Mining, and Industrial applications, including multi-layer boards, rigid-flex PCBs, and high-density interconnect (HDI) boards.

Our company holds relevant industry certifications to ensure compliance with stringent quality standards for Defence, Medical, Mining, and Industrial sectors. (please provide link to certificatiosn section here)

We employ rigorous quality control measures throughout the design and manufacturing process, including thorough design reviews, advanced testing procedures, and strict adherence to industry standards. We invest heavily in machinery and equipment that ensures accuracy and quality testing which provides confidence in speedy delivery.

Yes, we offer services for both prototype PCBs for concept verification and large-scale production runs, tailoring our approach to meet your specific project requirements.

Our team utilises industry-standard CAD tools for PCB design, including advanced software packages that cater to the complex requirements of Defence, Medical, Mining, and Industrial applications.

We utilise specialised design techniques and materials selection to ensure our PCBs can withstand extreme conditions often encountered in Defence, Mining, and Industrial applications across all environments.

Turnaround times vary depending on the complexity and scale of the project. We have built a strong reputation on delivering efficient services while .maintaining our high-quality standards.

Yes, we provide comprehensive support throughout the product lifecycle, including design consultation, prototyping, testing, and assembly services to ensure the success of your electronic projects.

Electronic Product Prototyping: Key Steps and Common Pitfalls

Why Market Research Matters For Product Development: Avoid This Crucial Mistake

Thermal Management: The Key to LED Longevity

Proven PCB Design Techniques for Electromagnetic Compatibility Success

Understanding PCB Assembly Costs: Key Factors to Consider

Enhancing Australia’s Electronic Warfare Capabilities

Optimising EMI Management in PCB Design

Established in 1997, Masters & Young is a market-leading, high-end electronic design and manufacturing company. Our experienced team is focused on providing solutions for a wide range of industries including defence, medical, aerospace, healthcare.